Japanese plastics manufacturer, TechnoLab, has started using plastic waste from Japan’s oceans to make home interior goods and furniture. This project aims to bring recycling activities to local towns and overseas.

The crowdfunding and community action initiatives it is carrying out for those projects may help create a model for how to make the recycling sustainable.

In the first part of its project, TechnoLab has made outdoor-use tableware from plastic washed up on the shores of beaches in the Shonan region in Kanagawa Prefecture, where the company is located. The products, marketed under the brand name “reBirth,” went on sale at the PARCO department store in Shibuya, Tokyo, in November.

It takes about five 500-milliltre PET bottles worth of plastic to make one of the plates. That’s only a small fraction of the estimated 150 million tons of plastic marine waste already existing in the world.

Eyeing broader shores

An estimated 8 million tons of plastic ocean waste is produced each year. A large percentage of that reaches Japan’s shores. TechnoLab plans to share its technology to help local towns besieged by the trash put it to good use. It plans to hold workshops with local municipalities to gather the plastic and reshape it into various handicrafts.

It hopes these projects will help revitalize local towns and boost public understanding of the problem of ocean plastic waste.

The company even plans to take its plastic recycling “studio” overseas in the future. It cites research from Germany’s Helmholtz Centre for Environmental Research (UFZ) that estimates that around 90% of ocean plastic waste is released by about 10 rivers, including the Yangtze and Mekong. Consequently, TechnoLab wants to collect the waste from areas where those rivers meet the ocean, and craft it into useful things.

Crowdfunding dreams

To help realize the company’s dreams of expanding these recycling works, it is crowdfunding until January 2020, organized by the crowdfunding company CAMPFIRE. CAMPFIRE is jointly managing, with PARCO, the trial showroom of reBirth goods at the department store.

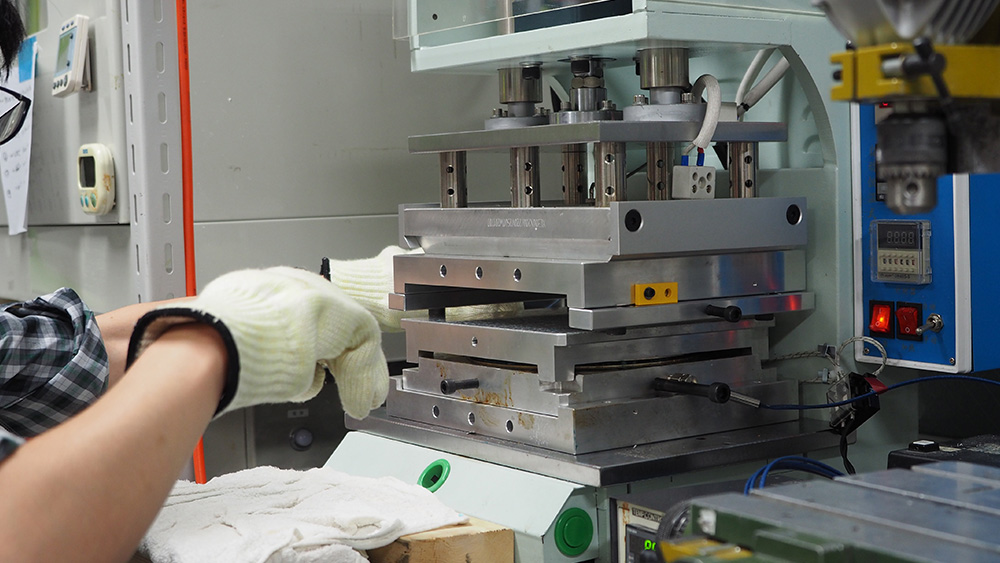

The funds are earmarked for the purchase of molds for insertion into a casting machine. It would allow TechnoLab to take it along to the beach to use on the spot, alongside a plastic shredder, in its recycling workshops.

The company’s use of local community assistance and volunteers, as well as crowdfunding, offer some solutions to the difficulties TechnoLab sees in achieving sustainable reuse of marine plastic waste. The high cost of collecting the plastic being chief among those issues.

While many companies around the world – mindful of consumers’ concerns – are starting to reuse marine plastic waste, what will happen when our minds shift to different issues?

How can we make the cheap, durable, malleable wonder that plastic is, less appealing?

[Website] reBirth[Website] TechnoLab