Although DIY has been a trend in recent years in Japan, taking electrical devices or home appliances to repair shops is still the norm for out-of-order products. In this area of daily life, most Japanese people tend to rely on professionals as often as possible. In fact, particularly in the modern technological world of urban areas, buying a brand new product is sometimes a cheaper and quicker option. So, why would we repair things ourselves now?

We visited Repair Lab in Setagaya, Tokyo to find out all the reasons why we should consider returning to this rather traditional idea of fixing things on our own. The Lab’s unique version of “repair” seems to provide a sense of empowerment in addition to the simple joy of restoring a product to usability once again. Kazumasa Kanei, the Director of FabLab Setagaya, talked to us about Repair Lab from the perspective of an operator/creator and explained the philosophy behind the project.

Repair Lab is held by FabLab Setagaya and is housed in the same facility. FabLab is located about one subway stop away from Shibuya, the center of metropolitan Tokyo. Intriguingly, the lab is nestled in a renovated former middle school building, now the Ikejiri Institute of Design (IID).

Interviewee Profile: Kazumasa Kanei

The Director of FabLab Setagaya at IID. After graduating Tokyo Institute of Technology with an engineering degree, worked in the field of human resource education. Has been in charge of PTA, a lab facility at IID since 2014. Teaches creation-related workshops for wide generations as well.

The Director of FabLab Setagaya at IID. After graduating Tokyo Institute of Technology with an engineering degree, worked in the field of human resource education. Has been in charge of PTA, a lab facility at IID since 2014. Teaches creation-related workshops for wide generations as well.How it started: The road to repair

In 2014, Kanei moved his operations into Ikejiri Institute of Design. He chose this building as a base from which he can collaborate with other innovative corporations (there are 50 corporations in the three-story building). Sharing and applying his ability to turn others’ ideas into prototypes was an appealing element of this co-working environment. His ambition didn’t stop there. Subsequently, he started FabLab Setagaya, and opened it up to the community.

There are so-called “Fab Labs” (an abbreviation for Fabrication Laboratory) operating all over the world, in approximately 1,600 locations. The MIT School of Architecture and Planning, the origin of Fab Lab, explains that “Fab Labs give users around the world the ability to locally conceptualize, design, develop, fabricate, and test almost anything. The engineering capability for design and fabrication at micron length- and microsecond time-scales opens up numerous possibilities for innovative solutions to common problems. Since local communities foster this innovation, it can lead to sustainable solutions.”

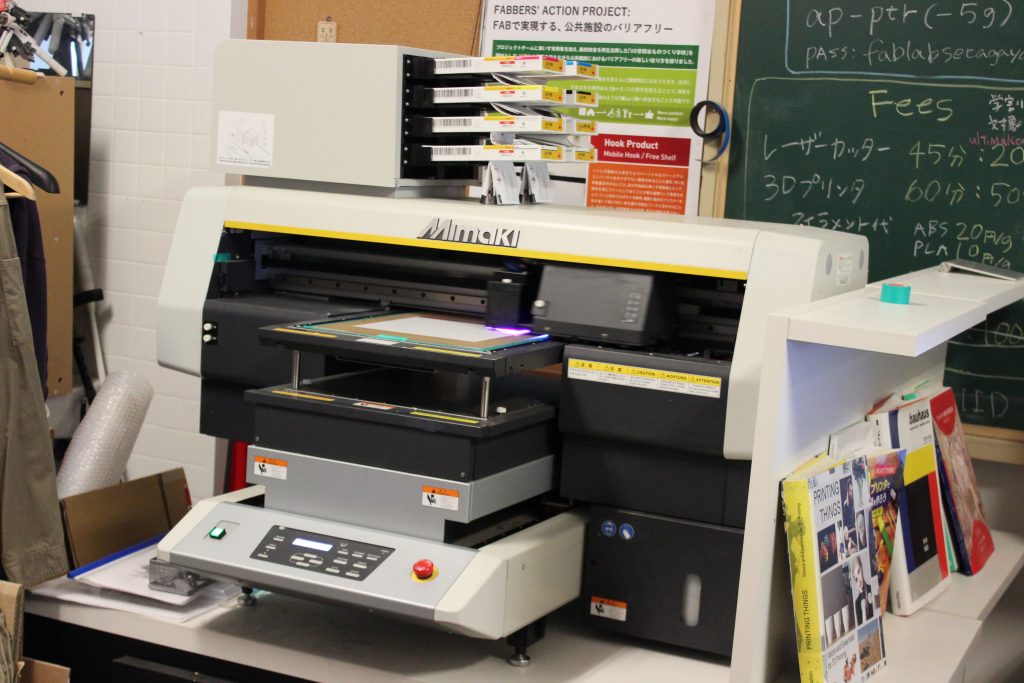

At FabLab Setagaya, community members come to use the machines and create freely anytime. Kanei says keeping the user fees low could attract a wider demographic. FabLab Setagaya opens its door seven days a week, hoping to serve the need for innovation whenever it arises. It is equipped with a variety of off-the-shelf tools, including 3D printers and a laser cutter as well as basic tools like screwdrivers and saws.

The Fab Lab’s focus on “How to make almost anything” led to the concept “How to fix almost anything.” Kanei was fascinated by the idea, and he runs Repair Lab according to this slogan.

Repair Lab encourages problem-solving

Repair Lab opens on the fourth Sunday of each month, ever since November 2018. All the tools at the FabLab are available to the Repair Lab participants for their repairs. The Lab itself does not make profits because it doesn’t charge participants at all. With the limited funds available, it is understandable why they don’t advertise widely. Furthermore, they are not aiming for profits nor a higher profile.

Four or five people can participate in each Repair Lab session. Participants bring in what they want to repair, and the staff help them from the beginning to the end. The advisor, IGZY (Iguchi), a retired engineer, locates the cause of problems first. Understanding the problem is the first step to fixing anything—the philosophy at Repair Lab. Once the cause is found, the repair begins.

Repair Lab has helped parents who want to fix broken toys, a man in his fifties trying to repair all of his home appliances, and a woman wanting to fix her favorite lamp she bought overseas. Most of them simply seeking to fix broken things. Sometimes they need to come in more than once in order to complete a repair. However, Repair Lab cannot guarantee repairs to everything.

Kanei says that the goal of Repair Lab is not solely repairing, but to show everyone ways to fix problems themselves. The result—whether a broken item ends up being repaired or not—isn’t the focus here. “We are not a repair ‘shop.’ I want to communicate that better to the participants,” says Kanei. The experience is a bit different from, for instance, watching Youtube to fix home appliances. Kanei values the process to get to the answer, and he wants to guide users to think for themselves. Nevertheless, the joy participants gain from the accomplishment is memorable and empowering.

One repair can lead to a self-sustaining life

Sometimes, people as young as elementary students participate in the Repair Lab. Despite the undeniable joy of taking apart products and trying to fix them, Kanei reveals that his ultimate goal is to guide children to become interested in creating. If children can create things themselves, he believes their future will be much more fulfilling because they are able to adapt their efforts to meet their individual needs. “One step before learning to create is to repair,” Kanei passionately states.

He also notes: “Today, many people seem to have so little experience working with basic tools. Fixing things is easier than they think. Opening and closing a lid sometimes fixes the problem. I don’t want them to give up and throw things away just because they can’t use something anymore.” We can only imagine the amount of electronic waste it could reduce if every one of us starts putting this idea into practice.

Kanei is the type of person who likes to live comfortably and conveniently, just like most of us. Because the technology has developed this far, the quality and functions of many products are the closest ever to where we want them to be. Using what’s available is a logical option. Although Kanei sees electronic waste as a serious issue, he remarks, “I don’t necessarily run Repair Lab to reduce waste. I am not fond of the idea of continuing to use things I dislike simply for the sake of the environment. Rather, I want people to realize they have the ability to fix anything. Well, almost anything.”

It seems that Repair Lab had a solid start, and it is on track to achieve their mission. Kanei tells us it is vital to continue running it, even for the benefit of one participant.

Kanei wishes the culture of repair to become more familiarized in Japan, and he wants to help with that. At the same time, building a better platform of “monozukuri” (creation in Japanese) to host foreigners who visit Japan is one of his goals as well. Kanei’s vision continues to grow.

There seems to be no shortage of technology, resources, or material goods in modern Tokyo. However, nonetheless, having the option to create things for ourselves leads to more possibilities, including sustainable solutions for the future. This may be the best time to develop our own creative potential, given the availability of guidance and expert instruction from organizations like Repair Lab.