Glass is a material that everyone sees almost every day but rarely notices. In any city, it is nearly impossible to look around without seeing glass in every direction. From residential and commercial windows to car windshields, and even the screen in front of you—glass is truly ubiquitous. Our lives are surrounded, protected, and supported by glass.

But what glass is made from? The main raw material of glass is silica sand, commonly known as “sand.” However, tracing the glass supply chain reveals that the world is currently facing a “sand shortage,” due to rising construction demand from population growth. Despite glass having a long lifespan and the ability to be repeatedly recycled if melted down, its potential for resource circulation remains largely untapped. According to Japan’s Ministry of the Environment, the recycling rate (cullet usage rate) for flat glass stands at only 36% (as of 2013). This figure even includes the cullet from rejected items in the production process, meaning that the actual recycling rate for glass recovered from demolition sites remains low.

Japan imports sand from distant countries and uses a massive amount of energy to produce flat glass. However, this glass often gets crushed and landfilled without being recycled, even though its lifespan should outlast the building itself. To address these challenges in the glass supply chain and create a circular economy where glass is continuously recycled within the community, an initiative has quietly begun in Suwa City, Nagano Prefecture, known for Lake Suwa. The company taking this first step is AGC Inc., one of the world’s leading glass manufacturers.

AGC Inc. has long worked towards effective resource utilization by developing highly recyclable glass products and conducting various glass recycling projects, such as trial initiatives for recycling solar panel covers. In September 2024, they succeeded in a groundbreaking collaboration with 7-Eleven, achieving the first resource circulation for glass components used in store materials in Japan. To further their efforts towards creating a circular glass economy, AGC began a regional co-creation project in March 2023 in collaboration with “SUWA Glass Village” to establish glass recycling in Suwa.

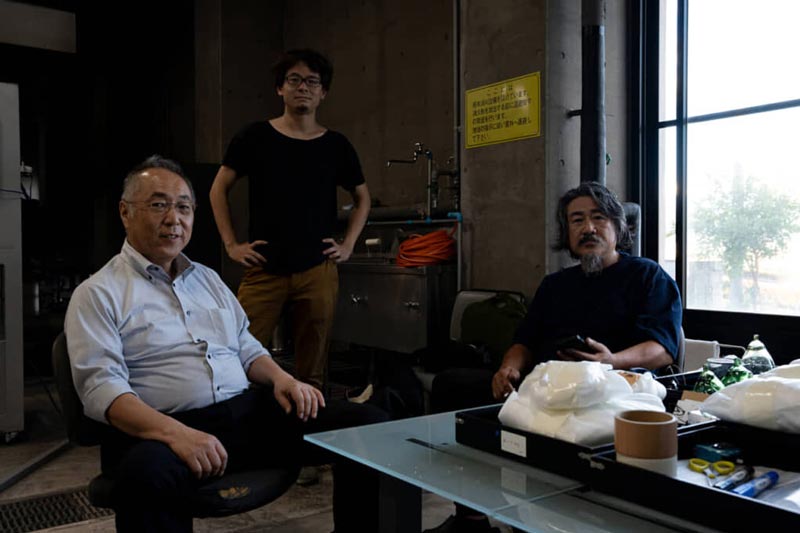

Why has a global glass manufacturer like AGC decided to start a glass recycling project in Suwa? What kind of future are they envisioning beyond this effort? We spoke in detail with Koji Nakagawa, Manager of Sustainability Promotion at AGC’s Corporate Planning Headquarters, who leads the glass recycling project in Suwa, about their initiatives in the area.

Redefining the “visibility” of glass

“Is it really okay to keep producing massive amounts of transparent glass?” Nakagawa wondered. “Given that the raw material for clear glass is finite, won’t we hit a wall eventually if we don’t change our values?” This question marked the beginning of initiatives in Suwa.

Nakagawa, who felt uncomfortable about the sheer volume of transparent glass being produced and discarded, began exploring alternative ways of glassmaking. One idea was whether it might be possible to establish a glass industry in regions with abundant local sand, like the deserts of Africa. Through his research, Nakagawa found Koji Murayama, an artist from Kaiba Glass Studio, who was creating glass from Saharan sand. Instead of clear glass, his creations reflected the colors of the sand’s origin.

Nakagawa immediately contacted Murayama to see if AGC could collaborate with his Morocco-based project, and in 2019 they began building a shared vision for an African glass industry. Although activities in Africa were suspended due to the COVID-19 pandemic, Nakagawa and Murayama remained in contact. This partnership reminded Nakagawa once more that what they used was not just raw material, but a natural, planetary resource.

At the same time, within AGC, Yohei Kawai, Nakagawa’s colleague, had launched “UNOU JUKU” (meaning “Right Brain School”), an internal community that focused on tackling future challenges, such as sustainability, using creativity and emotional engagement. Inspired by Murayama’s vision of crafting glass imbued with the colors of the land, Nakagawa and Kawai began the “Terroir of Materials” project together with Murayama. They melted sand from different locations, attempting to capture the local “memory” within the material.

For the first phase, they produced glass from the Tottori Sand Dunes, as well as other local mines. The second phase took place in Toyama, where they used sand from the Jinzu River. The term “terroir” comes from the French word terre, meaning “land,” and typically refers to the influence of geographic, geological, and climatic conditions on crops like grapes used in wine production.

For most people, “glass” calls to mind the image of clear, colorless material. However, the glass produced under the “Terroir of Materials” project isn’t transparent, but faithfully reflecting the colors of the local sand used in production. Although they may distort the original image when viewing through it, the materials’ origin are highlighted more vividly.

Through the industrialization of glass manufacturing, the connection between the material and its place of origin has been lost over time. The “Terroir of Materials” project aims to recover this link and invite people to reconsider its value.

The destined meeting with Suwa Glass Village

In 2021, Nakagawa and Kawai launched the “Sustaina-Lab,” a project aimed at addressing sustainability challenges in collaboration with individuals both inside and outside the company. The first guest they invited was Momona Otsuka, who works in Kamikatsu Town, Tokushima Prefecture, known for its zero-waste initiatives.

During the event, Nakagawa learned that while Kamikatsu has achieved an impressive recycling rate of 80%, glass is still not being recycled locally. This insight led Nakagawa to participate in the “GREEN WORK Kamikatsu” held in the area. He came up with the idea of creating a small-scale glass melting furnace in Kamikatsu to enable local recycling of glass. However, the project faced obstacles related to securing resources and equipment investment, ultimately hindering its completion.

Continuing his search for ways to establish a new local glass industry that connects with local materials and circulates glass within the community, Nakagawa had a serendipitous encounter on July 29, 2022. He met Naohiro Iwanami, chairman of the “Suwa Glass Village” Museum of Contemporary Glass Craft in Suwa, and also the 28th head of the historic Iwanami family of the Shimosuwa Honjin Inn.

Nakagawa: “It all started with Mr. Chimura, a lecturer at the Glass Art Research Institute at Tokyo University of the Arts, with whom we have had a long-standing relationship. He had been discussing with Suwa Glass Village to explore their potential collaboration. When he heard that dredged sand was being disposed of from Lake Suwa, he came up with the idea that the ‘Material Terroir’ project, which I had been working on with Mr. Murayama at AGC, might be a solution to utilize the dredged sand in Suwa. Then Mr. Chimura reached out to me, and on the unforgettable date of July 29, I visited Suwa. That’s when I met Mr. Iwanami at Suwa Glass Village, and on the next day, July 30, he showed me around. It was then that I discovered the presence of an unused glass workshop at the Glass Village. Seeing the small, dormant glass melting furnace, I thought it could achieve what Kamikatsu couldn’t: local glass recycling.”

Inspired by his time in Suwa, Nakagawa revisited the area in August during his summer vacation. He found a kindred spirit in Iwanami, who also wanted to bring the dormant furnace back to life amid changing times. This shared passion led Nakagawa to decide that AGC would start a local glass recycling project based in Suwa.

Having secured internal approval, Nakagawa, along with Murayama, began the refurbishment of the furnace. In an impressive turnaround, on April 23, 2023, just six months after meeting Iwanami, they succeeded in relighting the long-dormant furnace at the Glass Village workshop. The occasion became a historic day for the local community, with the mayor of Suwa City and the chief priest of Suwa Taisha Shrine also in attendance.

Creating glass from Suwa’s sand

After launching the project, Nakagawa and Murayama began by experimenting with making glass using sand from Lake Suwa. Every year, a large amount of sand is dredged from Lake Suwa and discarded, and this dredging is crucial to maintain the lake’s navigability. Since its maximum depth is only 4.7 meters, failing to remove the sand would affect boat traffic and hinder the local fishing industry, which is a key part of the regional economy. Additionally, maintaining the lake’s depth through dredging is vital for the conservation and restoration of the lake’s ecosystem and the surrounding environment, as shallower waters are more susceptible to eutrophication due to increased sunlight.

If they could utilize the dredged sand to create local glass, it could lead to a regenerative glass industry. The production of glass would then contribute to restoring Suwa’s natural environment. The glass made from the sand of Lake Suwa has a beautiful black luster, creating a sense of luxury. It could potentially become a distinct regional product in the future.

If we can ultilise this unique nature of glass, it may reveal a hidden potential of a regenerative glass industry, one that restores rather than destroys the environment. Made from sand, glass straddles the line between natural and artificial materials, embodying the principles of circular design.

At the same time, Nakagawa also began efforts to challenge and change the local community’s preconceptions about glass.

Nakagawa: “We needed to change the perception that glass is dangerous and difficult to recycle. For example, if you remelt glass from solar panels, it turns into green glass. Seeing this firsthand helped people understand why it happens. We also showed how bottle glass, if sorted by color and remelted, can be turned into beautiful colored glass again. We even demonstrated what happens when different types are mixed together. By having local waste management companies and construction firms witness the glass firsthand, they became interested and joined us as partners.”

Connecting material manufacturers and recyclers to close the loop

In the first year, Nakagawa focused on building relationships with the local community and researching and sharing the potential of glass. Starting in the second year, he began exoerimenting to establish a local glass recycling system.

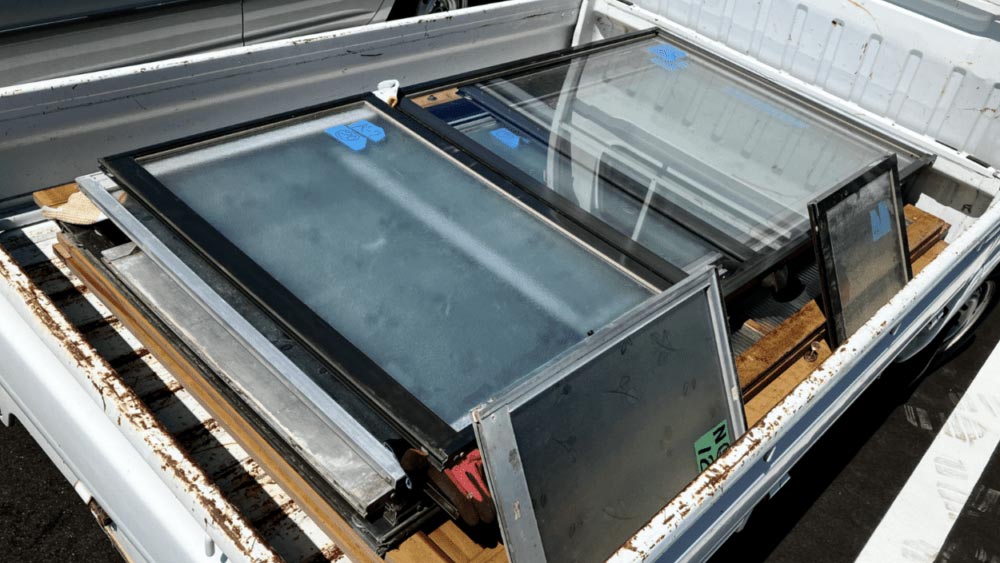

Nakagawa: “Second year on, we started collecting flat glass. Originally, AGC had been experimenting with retrieving and recycling glass during the demolition of high-rise buildings. However, the real potential for flat glass lies in low-rise residential buildings, such as houses. Low-rise residential demolitions are constantly happening, and local demolition contractors usually handle these jobs.”

“Thus, we are currently working to identify the disposal routes for glass from low-rise houses, to collect it in its flat form, and to create various reuse and upcycling options. This approach focuses on circulating materials locally as much as possible, while developing the system for large-scale recycling by sorting glasses and returning them back to AGC. If AGC is one of the options for utilizing the glass, it adds value to the collection process in the community. This kind of win-win collaboration could create shared value for everyone involved.

“We also got to see the demolition sites firsthand. Demolition workers usually want to recover aluminum sashes because of their value, but they end up breaking the glass on site. It’s mixed with other glass and ceramic waste, which leads to contamination and makes recycling difficult. However, if the glass is collected intact, it can be reused or recycled.

“With the cooperation of a local waste disposal company, Shinshu Takeei, we began investigating the types and quantities of glass generated during the demolition of residential properties before they are demolished. We have started sampling various kinds of glass—across different time periods and types—still in their window frames. To recover the glass without breaking it, we disassemble the window sashes one by one, enhancing the efficiency of the process and designing it as a dismantling procedure. We’re aiming to build a prototype process for the local area.”

In the traditional linear value chain, material manufacturers and recyclers are the furthest apart. But in a circular value chain, they become closely aligned. By coordinating with each other at the material level, these two groups can create a smooth infrastructure for local circular systems.

Nakagawa: “In designing the dismantling process, we need to clearly define quality standards for AGC and establish sorting rules. Currently, we are sampling each piece of recovered glass and analyzing its composition. Since AGC can also assess defects that occur during glass melting, we are now in the process of collecting samples. If contamination is present, the glass must be cleaned; if there are attached materials, testing equipment may need to be introduced. If not, just the dismantling work will suffice. Once these aspects are clarified, we hope to develop a prototype line in the community.”

Creating a glass recycling system at the community level requires collaboration not only with AGC, as the material manufacturer, but also with housing contractors, recyclers, and other players essential to local recycling efforts. The goal is to create a vision where everyone involved benefits, while steadily and meticulously building the framework through a hands-on approach. The connections and trust established with the local community through these processes become indispensable assets in manifesting a local circular economy.

A future where materials are return like shrine amulets

For AGC, crucial stakeholders are not only local businesses. To achieve glass recycling, Nakagawa has also been engaging in conversations with Suwa Taisha, one of Suwa’s treasures located near the shore of Lake Suwa.

Nakagawa: “We’ve been conducting workshops with the local community, including Suwa Taisha, to explore whether we can create a new souvenir from black glass made with sand from Lake Suwa. At shrines, amulets and talismans are always returned, right? The returned items are then ritually burned, but if they were made of glass, they could be remelted and used again. If amulets or talismans were made from glass, with the high return rate they already have, the shrine itself could become a collection point. We write ‘自続’ (self-sustaining) instead of ‘持続’ (sustained) to emphasize continuation, that the onus is on the individual. When it comes to the use of glass made from local sand, the community members are actively generating ideas and taking initiative.”

In Japan, there is a culture of returning amulets and talismans to the shrine. This cultural habit of “returning” can be mirrored in material recycling to create a new circular model for local products. Designing a circular model rooted in Japanese culture is an incredibly unique approach.

Lake Suwa is the “mirror” that reflecting the nature of Suwa

To ensure a circular system embeds long-term within a community, the future must be designed in a way that extends from the land’s nature, culture, and history. In this regard, Lake Suwa is indispensable when considering recycling in the Suwa region.

Nakagawa: “For the people of Suwa, Lake Suwa is both a treasure and a mirror reflecting their way of life. If anything goes wrong in the town’s environment or lifestyle, Lake Suwa gets polluted, but when everyone makes an effort, it becomes clean again. In that sense, having Lake Suwa nearby as visible nature we wish to coexist with is a great motivator for moving forward with recycling activities.”

Lake Suwa is an important commons for the people of Suwa, reflecting the state of their community like a mirror. Considering that mirrors themselves are made of glass, perhaps the most significant outcome of AGC’s efforts in Suwa is the preservation of a beautiful, pristine Lake Suwa.

To create the scenery we want to see beyond the glass

Residential and accommodation facilities are situated around Lake Suwa, and naturally, most of their windows face towards the lake. As long as the beautiful nature centered around Lake Suwa is preserved, people will want to put windows in their homes to see it, enjoying the view through the glass.

With this in mind, what might be necessary for the sustainable growth of the glass industry may not just be making glass itself, but maintaining the scenery that people want to see beyond the glass. What kind of future scenery does Nakagawa envision in Suwa?

Nakagawa: “I believe that the future of the community must ultimately be thought out by the local people themselves. Therefore, I think it’s not me but the local community that will draw Suwa’s future. However, the phrase ‘living in harmony with the land,’ as promoted by Mr. Iwanami of Glass Village, is an ideal I think is fitting. I believe our Material Terroir project was welcomed because it shares this foundational philosophy.”

The future of the community is built by its people. Nakagawa, like the “wind,” meets with the local people, who are like the “soil,” and this interaction creates various types of interactions. These outcomes are then woven back into the future of the region by the people. Through this cycle, the local culture and landscape are nurtured and passed down over time. Nakagawa’s use of the term “自続” (self-sustaining) conveys the same sentiment.

So, what future does AGC envision beyond the Suwa project? Nakagawa shared his thoughts in conclusion.

Nakagawa: “So far, we’ve focused on establishing a solid framework for co-creation within the community. Going forward, we want to partner with Shinshu Takeei to create a production line so that, even if it’s just a small amount, glass can return from Suwa to AGC. Eventually, we hope to expand this model to other regions.

“There are two thoughts I have about glass recycling. The first is about how far we should design the system. Glass can indeed be recycled and reused repeatedly, but since its lifespan is so long, reaching the second and third cycles would take 50 to 60 years. It’s hard to envision that far ahead. Therefore, at least designing the system so that the glass comes back to us is a start, and after 30 years, there will be new technologies and different methods for the next generation to consider for recycling. We must ensure sustainability by connecting people and technology continuously.

“The second point concerns AGC’s role. AGC aims to increase the recycling rate and has substantial production capacity for glass, but even then, it can only address about 30% of the glass discarded within Japan. Even if AGC’s furnaces were running at 100% capacity, 70% of the problem would remain unresolved. Thus, I believe it is also our responsibility, as a material manufacturer, to think about solutions for the remaining 70%, whether that’s setting up a reuse system by collecting flat glass intact or proposing alternative uses within the community. That’s what AGC is capable of doing.”

When considering the cycle of glass recycling, what matters now is designing the collection system. After that, the optimal way to recycle materials should be determined by the people of that time, using the technology available to them. In designing glass recycling, it’s not just about recycling but also about providing diverse options to create a system that addresses the industry’s broader problems. This is Nakagawa’s perspective of continuously pursuing the essence of circulating glass.

Editor’s Note

Nakagawa is drawing a sustainable blueprint for the future of the glass industry by addressing the sand used for glass, the land it comes from, and engaging the people living there. The Suwa project will reach its initial conclusion in about a year, but AGC’s challenge is only just beginning.

Due to its weight, glass is not environmentally suited for large-scale recycling involving long-distance transportation. However, it is an ideal material for creating small, localized cycles. As people work to establish glass recycling systems, they reconnect with their community’s nature, culture, and fellow residents, collaboratively building a new future. Nakagawa’s efforts have taught us a lot about the importance of designing localized circular systems. What will the Lake Suwa mirror reflect ten years from now? I am already excited to see that future landscape.

Originally published on IDEAS FOR GOOD.

[Website] AGC[Website] Suwa Glass Village (Japanese)

[Website] Kaiba Glass Works (Japanese)

[Website] Shinshu Takeei (Japanese)

More on circular economy in Japan

- 2026-03-05: Sangetsu and TEIJIN FRONTIER launch horizontal recycling system for curtains

- 2026-03-03: Takenaka Corporation releases Circular Design Build Concept Book

- 2026-03-03: Sustainable craft gin supporting Hakuba Village forest preservation

- 2026-02-28: FamilyMart stores soon to become reuse hubs for Bookoff services

- 2026-02-19: Japanese craftsman launches Repair Glass upcycling broken wine glasses