Fashion is the world’s second-largest polluter and water-intensive industry in the world. The clothes manufacturing process consumes resources such as water, energy, and chemicals. It also accounts for 10% of the world’s carbon emissions. In Japan, only 34% of clothing is recycled, and the rest are incinerated or end up in landfills. It needs to fill this prevalent gap.

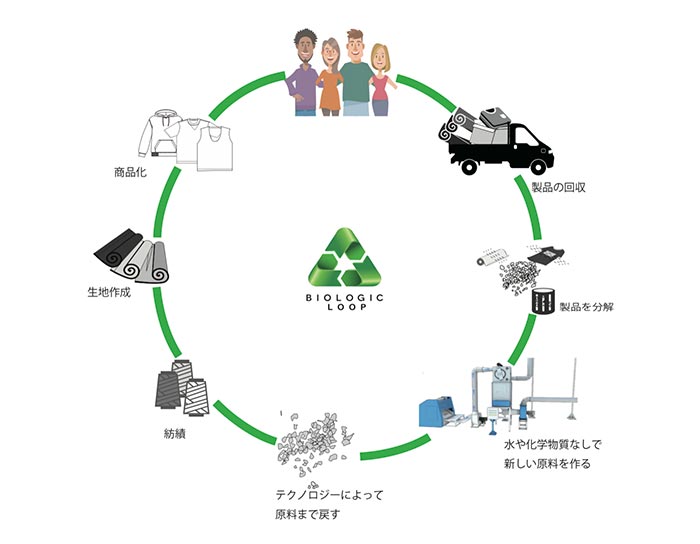

BIOLOGIC LOOP by BPLab is a recycling platform launched in August. It fills up this sustainability gap by connecting fashion manufacturers with fashion consumers to create a shift for fashion to become a sustainable industry. The core of the platform lies in the system of a circular economy.

There are three principles to a circular economy:

- Eliminate waste and pollution

- Circular products and materials

- Regenerate natural systems

These principles are reflected in the workings of the BIOLOGIC LOOP: unused clothing (in materials such as cotton, linen, wool, and its composite materials) are collected, sorted, and regenerated into new fibers using recycling technologies. Subsequently, these fibers are used to manufacture new clothing for sale, and the cycle repeats.

New clothing manufactured by recycled fibers is accompanied by colored tags; green for cotton/ linen, and red for wool. These tags also come with QR codes. Consumers can scan the QR code to obtain information about the materials of the product, and how it was recycled.

Not only do these initiatives allow fashion consumers to have the appropriate resources to practice sustainability, but it also equips them with access to learn more about ecofriendly living.

Moving forward, BPLab aims to conduct further research and development in new recycling technologies to realize a circular economy in the lifestyle industry.