In 2015, Toyota Motor Corporation announced the Toyota Environmental Challenge 2050, a set of six environmental challenges that the company aims to achieve by 2050. The focus of these targets is to reduce CO2 emissions and become carbon neutral.

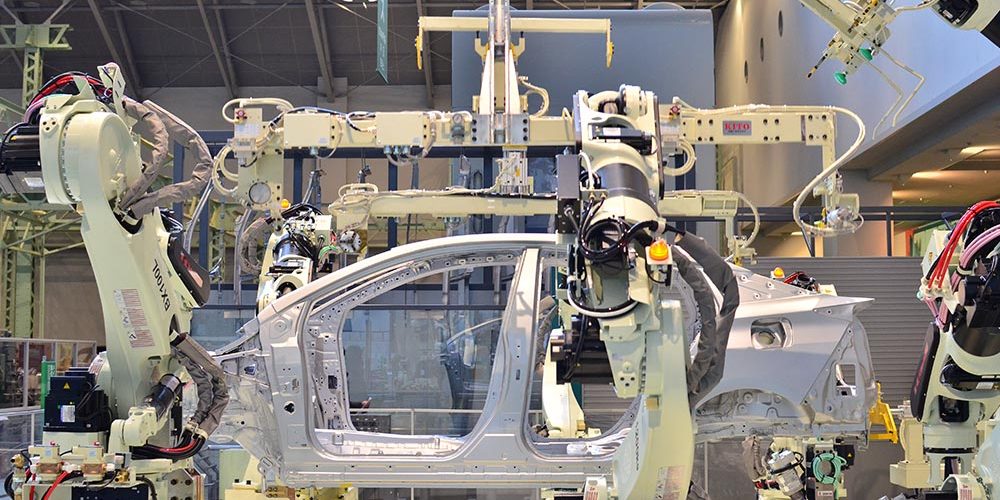

Carbon neutral is achieved when the amount of CO2 released is balanced by an equivalent amount of it being removed. Toyota aims to accelerate its carbon-zero targets by making their factories all over the world carbon neutral by 2035. This will be accomplished by transforming them into green factories.

Changes are to be made to identified processes emitting large amounts of CO2, for example, their painting, coating, and casting processes. Innovative sustainable technologies developed by the company would be implemented to improve existing production technologies for sustainability.

One new technology would be an improved coating process based on the concept of static electricity and rotation. This technology makes it possible to achieve maximum application efficiency with minimum paint, hence heavily reducing power consumption.

There is also research and development in removing the traditional painting process with a technology that incorporates paint coating and its resin molding process. Alternatively, adhesive films could be used in place of paint, and factories can avoid excessive emission of CO2.

Toyota’s shift towards sustainability translates to a domino effect in the manufacturing industry where suppliers of materials and parts are encouraged to go green. In fact, since 2020, Toyota has been expecting its suppliers to reduce their CO2 emissions by 3 percent.

To be sustainable and achieve Toyota’s carbon-zero targets, it is important to fulfill sustainability beyond manufacturing. The Life Cycle Zero CO2 challenge is one of Toyota’s environmental challenges dedicated to eliminating CO2 emissions throughout the entire vehicle life cycle, from the materials, manufacturing, assembly, maintenance, and disposal.

Achieving carbon neutrality allows a radical rethink of the future of manufacturing and how companies can transition into sustainable manufacturing.